What is NYRIM material?

NYRIM® is a polymer system of the polyamide type, which is characterized by exceptional toughness, variable stiffness, high abrasion resistance, low coefficient of friction, excellent puncture resistance and very good chemical resistance.

Chemically, NYRIM is a block copolymer of the A-B-A type on the basis of polyamide-6 and polyether. The individual segments are chemically bonded, which contributes to the optimal combination of copolymer properties.

Nylon-6 | elastomeric phase Nylon-6

NYRIM is not a designation for a single polymer. By changing the ratio of the input components of the formulation, the amount of elastomeric phase in the final product can be changed in the range of 10–40%, thereby fundamentally changing the product´s material properties.

The properties of the product can be further modified with various additives such as fillers, lubricants, flame retardants, protective systems against atmospheric influences, etc.

To a large extent, the described variability of the recipe composition enables the properties of the polymeric material to be adapted to specific applications and customer requirements.

Selection of NYRIM material properties at normal temperatures

How is NYRIM material processed?

At Promens Zlín we use the following technologies:

- RIM (reactive injection of unfilled systems);

- RRIM (reactive injection systems for filler systems);

- SRIM – structural reactive injection (injection of material into a mould with reinforcement – e.g. fibreglass);

- reactive casting technology.

The essence of RIM technology is the injection of a monomer mixture (final recipes) directly into the production mould, where the mixture subsequently polymerizes under specific conditions. After polymerization is completed, the finished product is removed from the mould.

With the NYRIM system, the required conditions for this process are a very low viscosity of the injected mass at a lower temperature than the temperature of the mould.

Unlike conventional injection moulding, where a viscous polymer melt is injected at high pressure into a mould significantly colder than the melt temperature, NYRIM technology uses only low pressure to transport and mix the reactive components, allowing large parts (tens of kilograms) to be produced on relatively small devices using light forms. Since monomer (not polymer) is injected into the mould, there is practically no internal stress or so-called “cold joints” in the products.

Material properties of the NYRIM system from the point of view of application possibilities

The most valued feature of the NYRIM group of materials is their exceptional toughness, which can also be controlled to a large extent by the content of the elastomeric component – in practice just by changing the ratio of the components of the recipe. NYRIM is also characterized by high abrasion resistance, low coefficient of friction, excellent puncture resistance and very good chemical resistance. Due to a certain absorbency, NYRIM has limitations for very precise products.

However, due to its ability to accept a large content of fillers, its properties can be further modified. Some examples include non-flammable recipes, materials with high weather resistance, materials with a reduced coefficient of friction, etc. Due to the possibility of dosing large amounts of fibrous fillers, parts with controlled anisotropic properties can be produced from the NYRIM material.

Within RIM systems, NYRIM is unique in its ability to be dyed in mass without the need for additional painting. However, if necessary, it is easy to paint.

It is also important to use it in products with a strict recycling requirement – NYRIM is easily recyclable.

RIM technology details from the application point of view of the NYRIM system

The NYRIM reactive injection system enables the production of large products without residual stress, products with large wall thickness and different filler contents. As the liquid reactive components are impregnated into the mould at low pressure, significantly less expensive moulds can be used for production than is necessary for conventional systems. Low viscosity of the reactive components allows excellent reproduction of the mould surface.

The total investment costs of the technological unit are significantly lower than for conventional systems, while larger and more complex products can be produced. The production of large parts can therefore be economical even for small series of approx. 1,000 pcs/year. The competitiveness of this technology is the highest for medium production series, i.e. tens of thousands of pieces per year. For smaller products, it is common practice to place multiple products in one mould.

In summary, in terms of technology, NYRIM is the most advantageous for large thick-walled products in medium series.

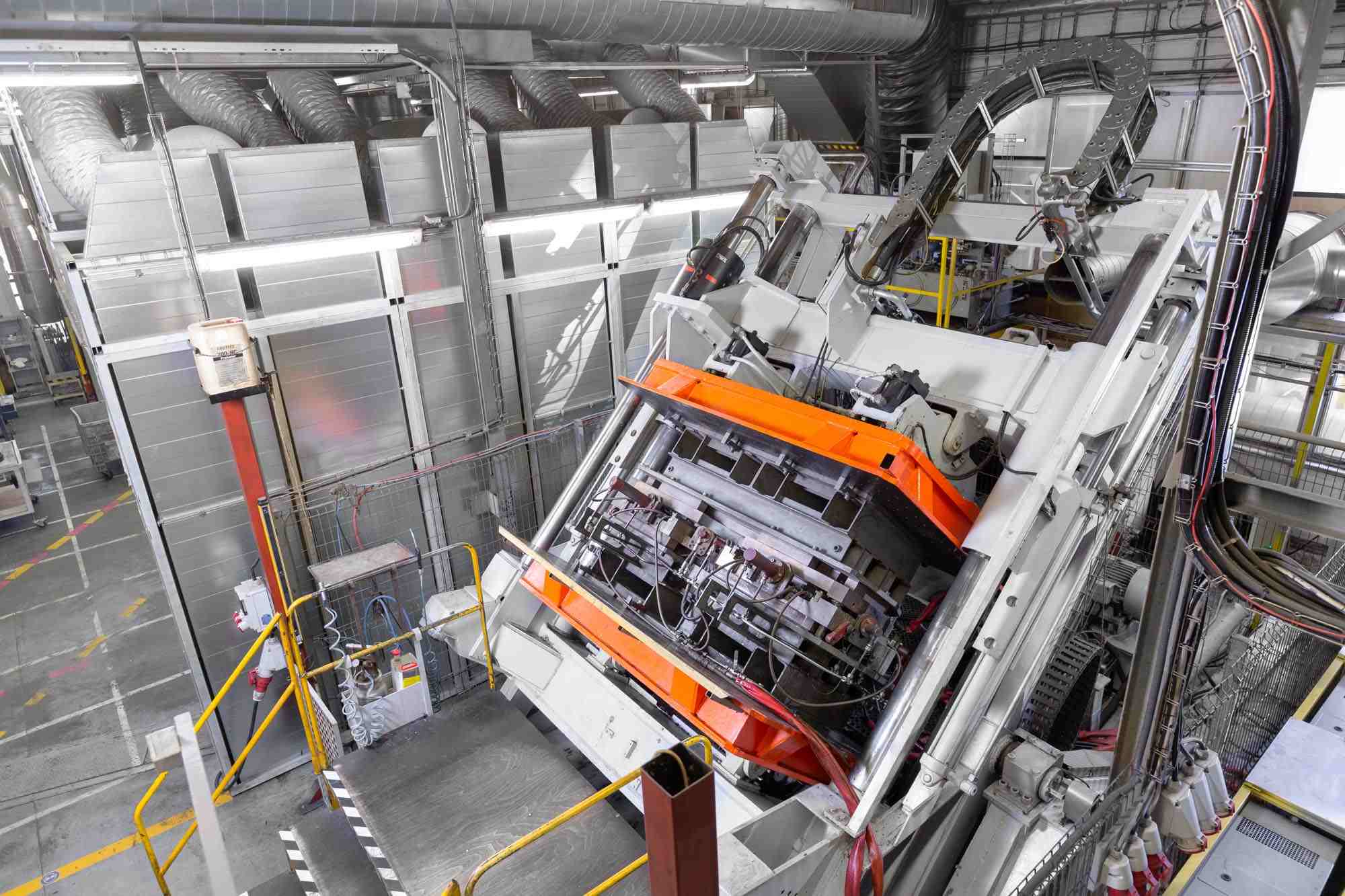

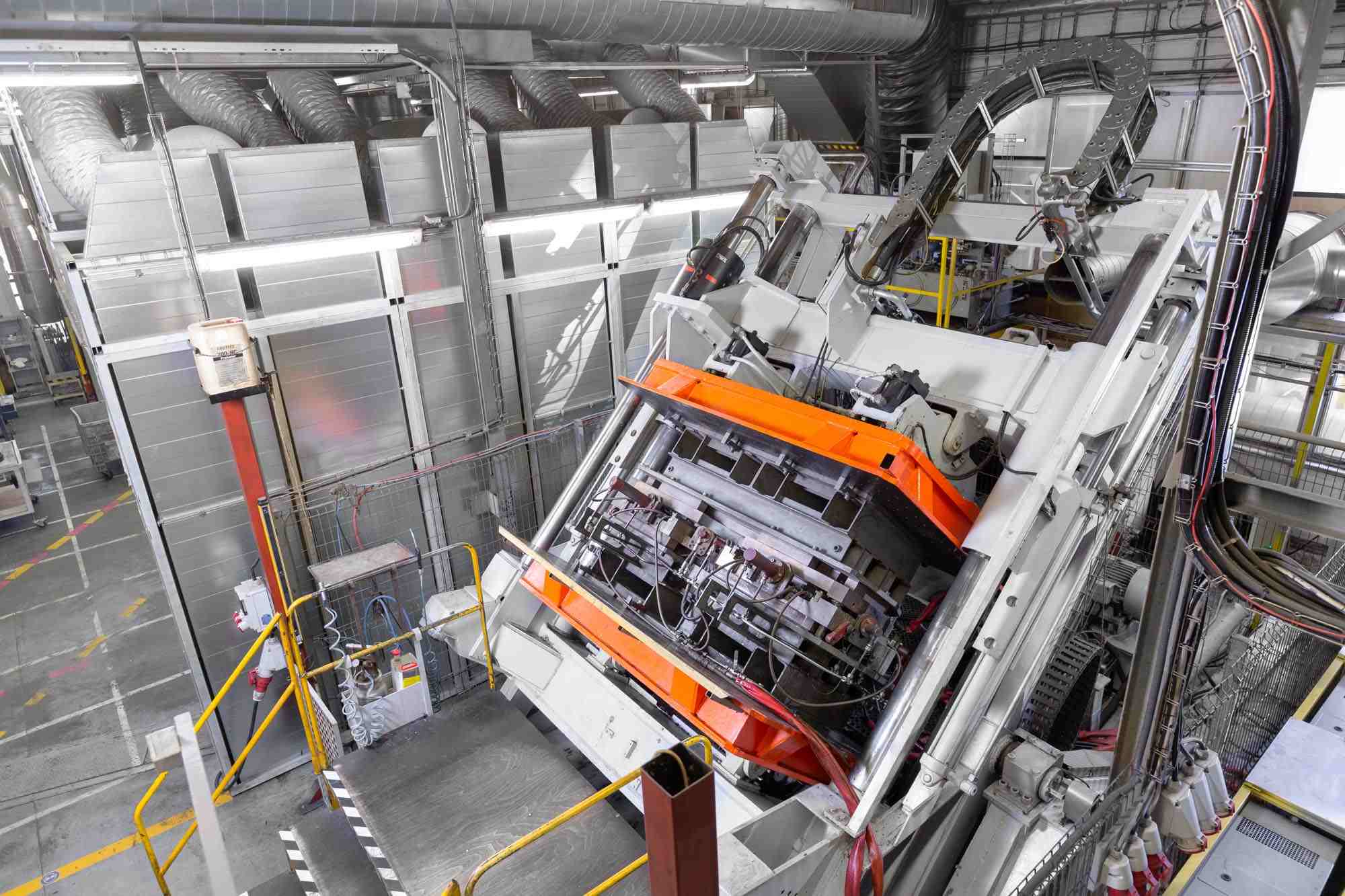

Production photos