World Class Manufacturing – the rules for top production. We did very well in the recent audit!

After much intensive work on improvements to our production processes, we were rewarded with a successful World Class Manufacturing audit.

Promens Zlín’s final score? 16 points!

What does gaining 16 points mean to us?

“First of all, progress. With our score moving up from last years´ 11 points, we exceeded our own expectations.

The recognition of our efforts is also important, as is the trust this generates in relation to our further cooperation with IVECO.

Last but not least, the taste of victory. Despite the many complications associated with COVID-19, we still managed to pass the WCM audit with flying colours.”

Lucie Ťavodová, Industrial Engineer at Promens Zlín

What´s next?

“With the new year come new ambitions. We plan to strengthen the team, while focusing on achieving a total of more than 20 points, which opens the path for us to implement other technical pillars. Among other pillars, we want to go up by 2 points.

We have a new direction, new challenges, new projects and a focus on new model areas.

And, as soon as the situation allows, a celebration.”

Lucie Ťavodová, Industrial Engineer at Promens Zlín

At Promens Zlín, we create a culture of continuous improvement. We know very well that each and every one of us plays an important role in innovating our processes.

Let’s take a look at the World Class Manufacturing methodology together.

WCM? Never heard of it!

World Class Manufacturing (WCM for short) is a structured, rigorous and integrated production methodology adopted by Fiat-Chrysler-Automobiles´ (FCA) production plants, as well as other companies around the world.

The WCM methodology affects the entire organization – from safety through the environment, maintenance, controlling, human resources, logistics to quality.

The primary goal of WCM is continuous improvement in all areas, not only in production, so that the quality of the final product is guaranteed and customer expectations are met.

The projects developed within the WCM methodology, which rely on a high level of employee involvement, focus on eliminating all forms of waste and losses with the ultimate goal of achieving “0 accidents, 0 losses, 0 waste and 0 failures” within the company.

World Class Manufacturing and its pillars

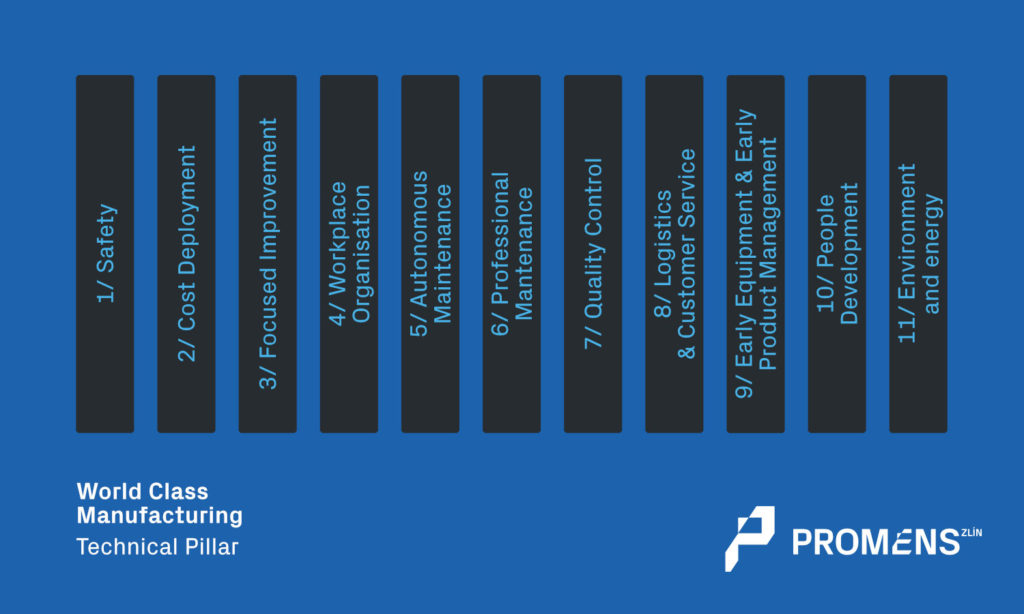

The WCM system consists of ten technical and ten managerial pillars.

Within each pillar, we can gradually increase our level and measure the results through regular audits.

Ten technical pillars of WCM

Ten managerial pillars of WCM

History of WCM (not only) at Fiat

WCM was developed by Fiat and its partner companies in 2005. As of this year, all Fiat Group companies use WCM as a tool for achieving operational excellence.

As a result, WCM was launched in Fiat’s automotive and powertrain divisions, Maserati, Lancia, Alfa Romeo and, in relation to Promens Zlín, CNH (manufacturer of Case agricultural machinery and New Holland tractors), which is owned by Fiat.

Within CNH, the WCM method is also used by the truck manufacturer Iveco, our other major customer.

Further information on WCM / wcm.fcagroup.com