Promens Zlín: The only European producer using all RIM and SMC systems and VF process inhouse.

Tier1 Full service supplier.

Sketching

& Stylistic design

CAD/CAM

& Prototype

3D

Implementation & Simulation Analysis

Who we work for

The result of our work is the movement of machines and vehicles, which make work easier and shorten distances.

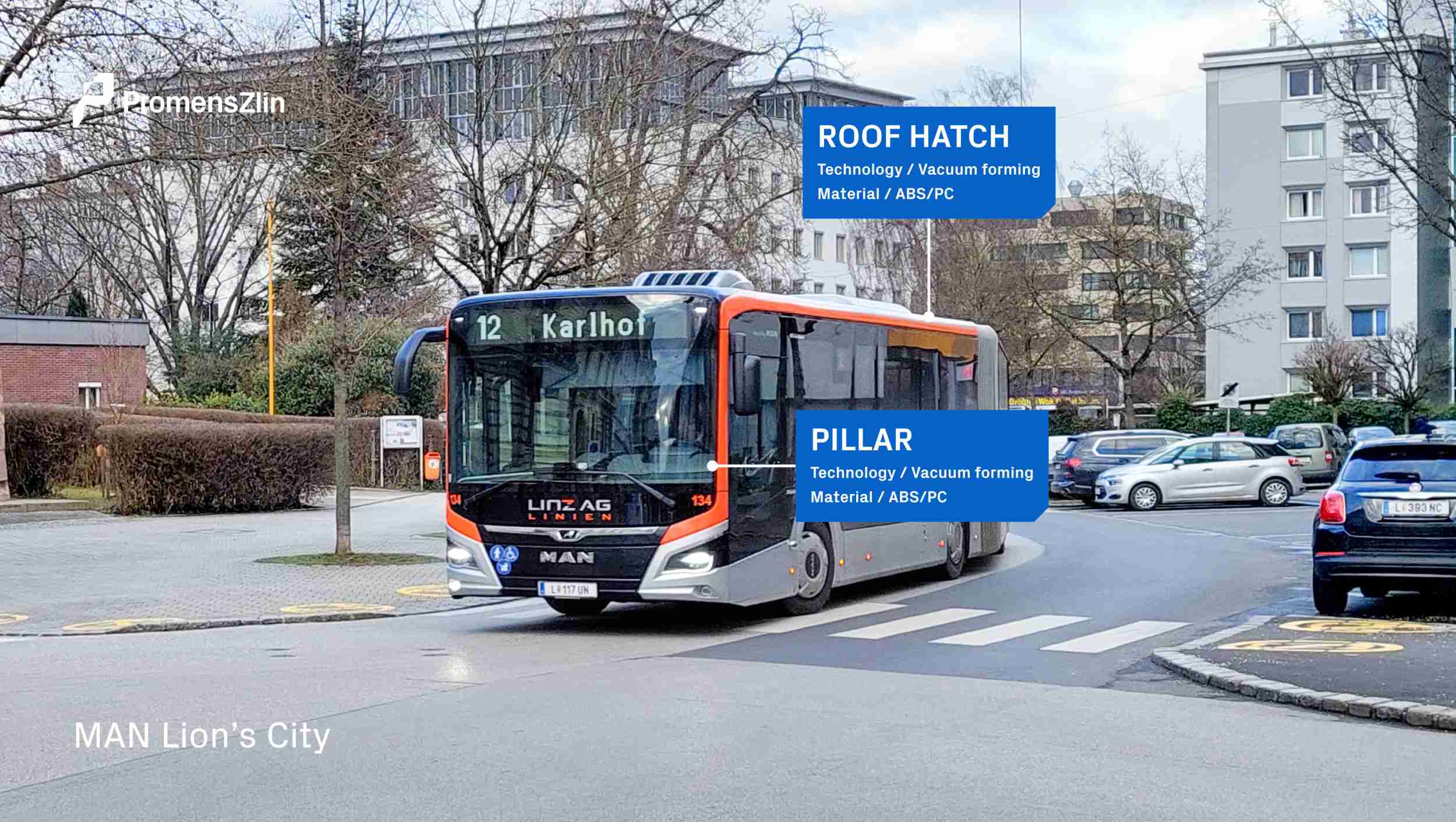

Buses

Our company is one of the most sought-after manufacturers in the field of buses.

We have the most comprehensive range of plastics technologies – DCPD-RIM, vacuum forming, rotary casting, injection moulding, PU-RIM and pultrusion. From a single part to a complete solution of the driver’s compartment.

Construction machinery

Loaders, dumpers, vibratory rollers, excavators and other machinery and equipment. We are well aware of the demands in this segment.

Mechanical properties, temperature resistance, visual demands, serial production, variability and other challenges. We have extensive experience in this field, whether it concerns the production of individual parts or complex assemblies and functional units.

Vans

We have more than 20 years of experience in the design, development and production of rear spoilers using PU-RIM technology, which is a suitable solution for medium-series projects. We always approach such projects comprehensively.

Supplying the solution includes the design of suitable packaging, construction and the production of all tools. We supply the product, including the surface treatment, in the appropriate quality and the required range of colours.

Passenger Vehicles

We finalize the construction of parts, including the appropriate assembly solution, reinforcement or incorporation of functions such as, for example, brake lights or washer nozzles.

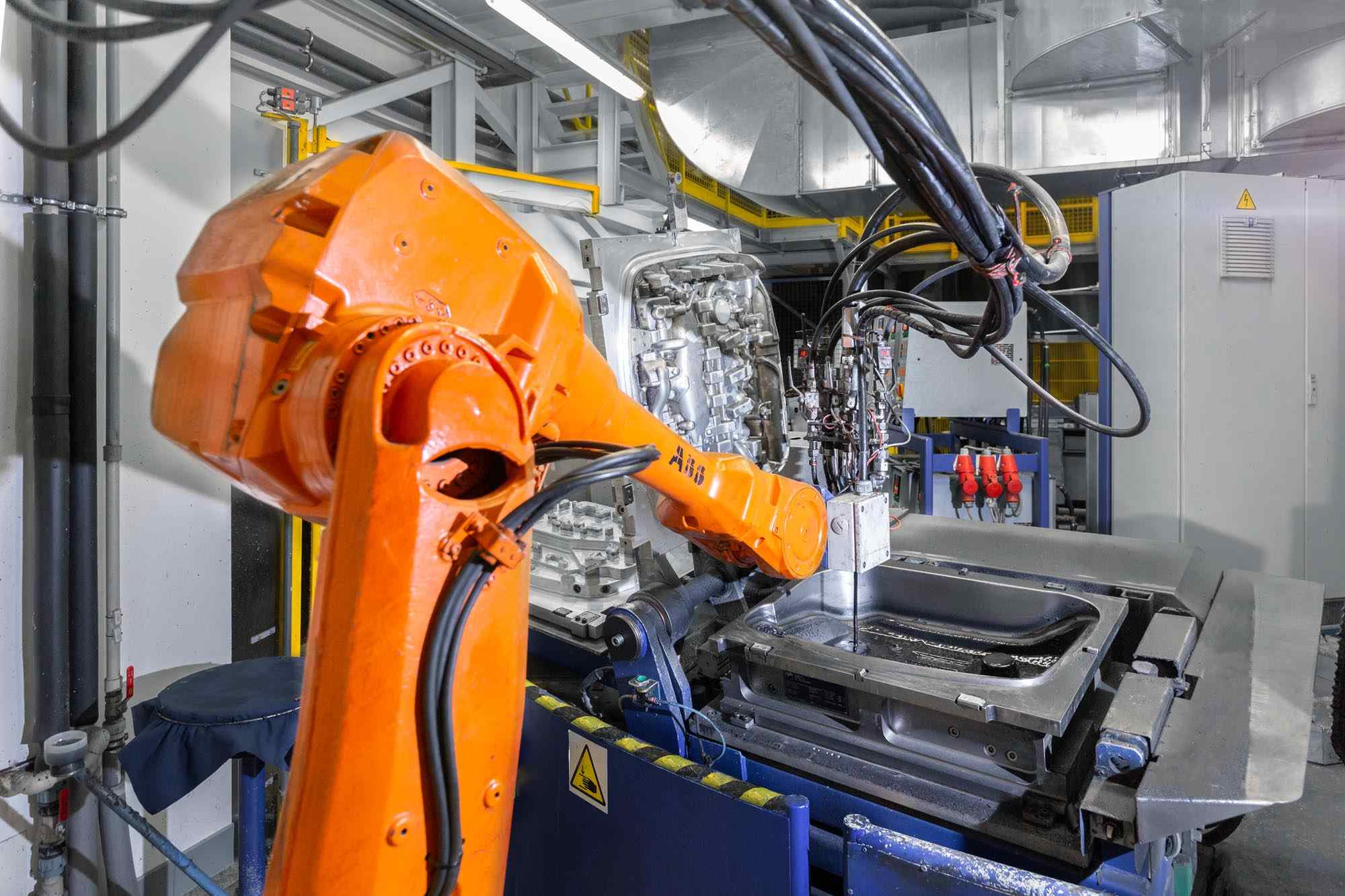

We also have unique experience in the NVH field of engine covers, the insulation properties of which meet the requirements of the world renowned premium brand vehicle manufacturers. For this, we use a special production line and robotic workplaces with a capacity of up to 300,000 pieces per year.

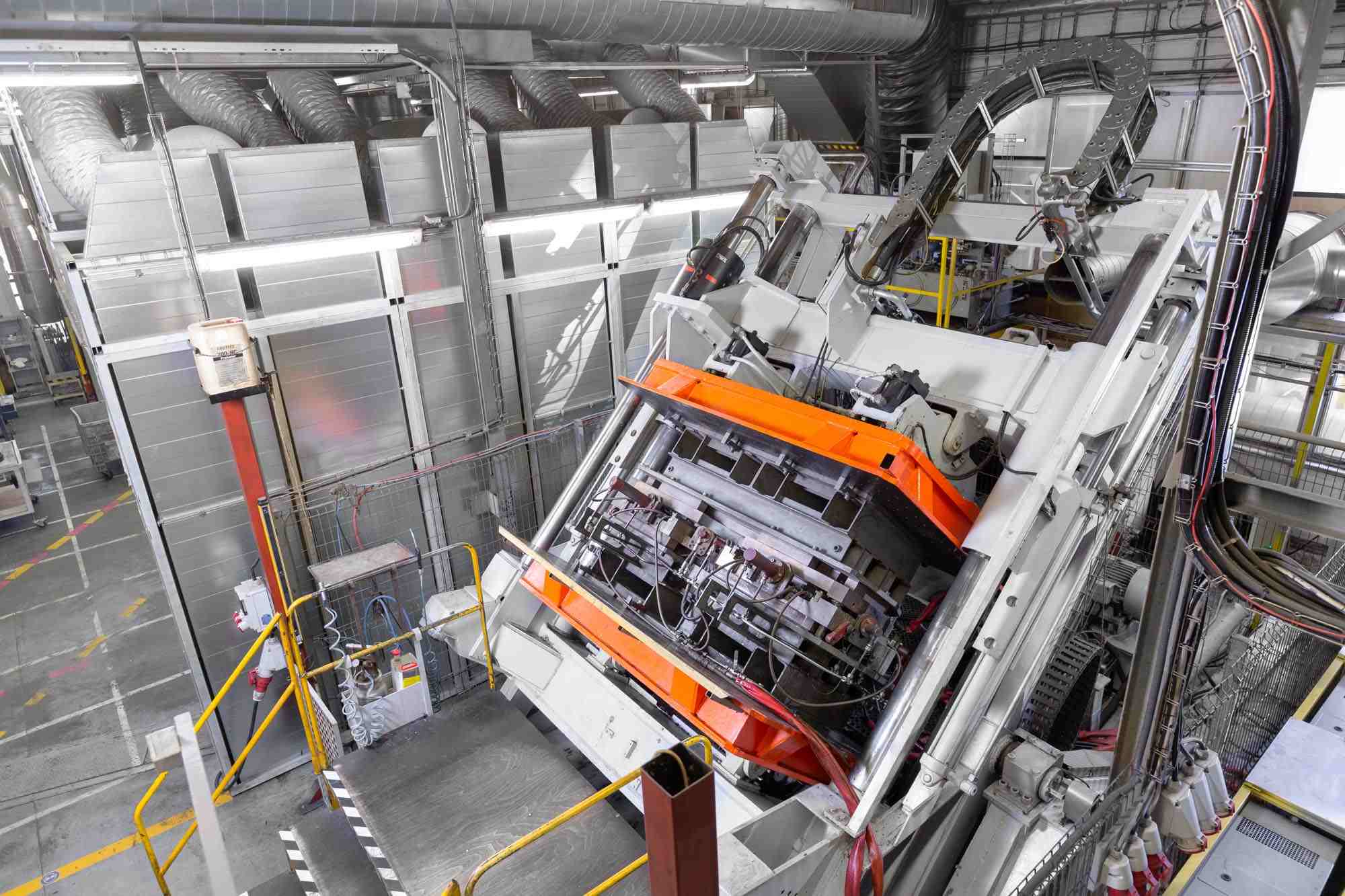

Technology at Promens Zlín

We are exceptional in terms of the scope and combination of technologies we apply, as well as for the plethora of innovations we have introduced.

We work for the best

News in the Promens Zlín world

Tomáš Baťa said “He who stands still for a while, falls behind.” We don´t.

Movement and dynamics are the result of our work – with regards to machines and humans alike.